Engineered wood

Blending heritage with eco-innovation to redefine wood's strength.

Krivaja glued laminated timber

Krivaja glulam is an engineered wood product, composed of fir and spruce wood laminations that are bonded together with strong, waterproof adhesives -all manufactured in accordance with EN 386 / EN 14080.

Glulam's most remarkable advantage lies in its incredible versatility, enabling it to be manufactured into almost any desired shape while retaining its exceptional load-bearing capacity. Renowned for outstanding dimensional stability, efficiency, and adaptability, glulam beams effortlessly make for innovative designs without compromising on quality and strength. All this makes them the natural and cost competitive choice for every project.

Viceroy Kopaonik, Serbia

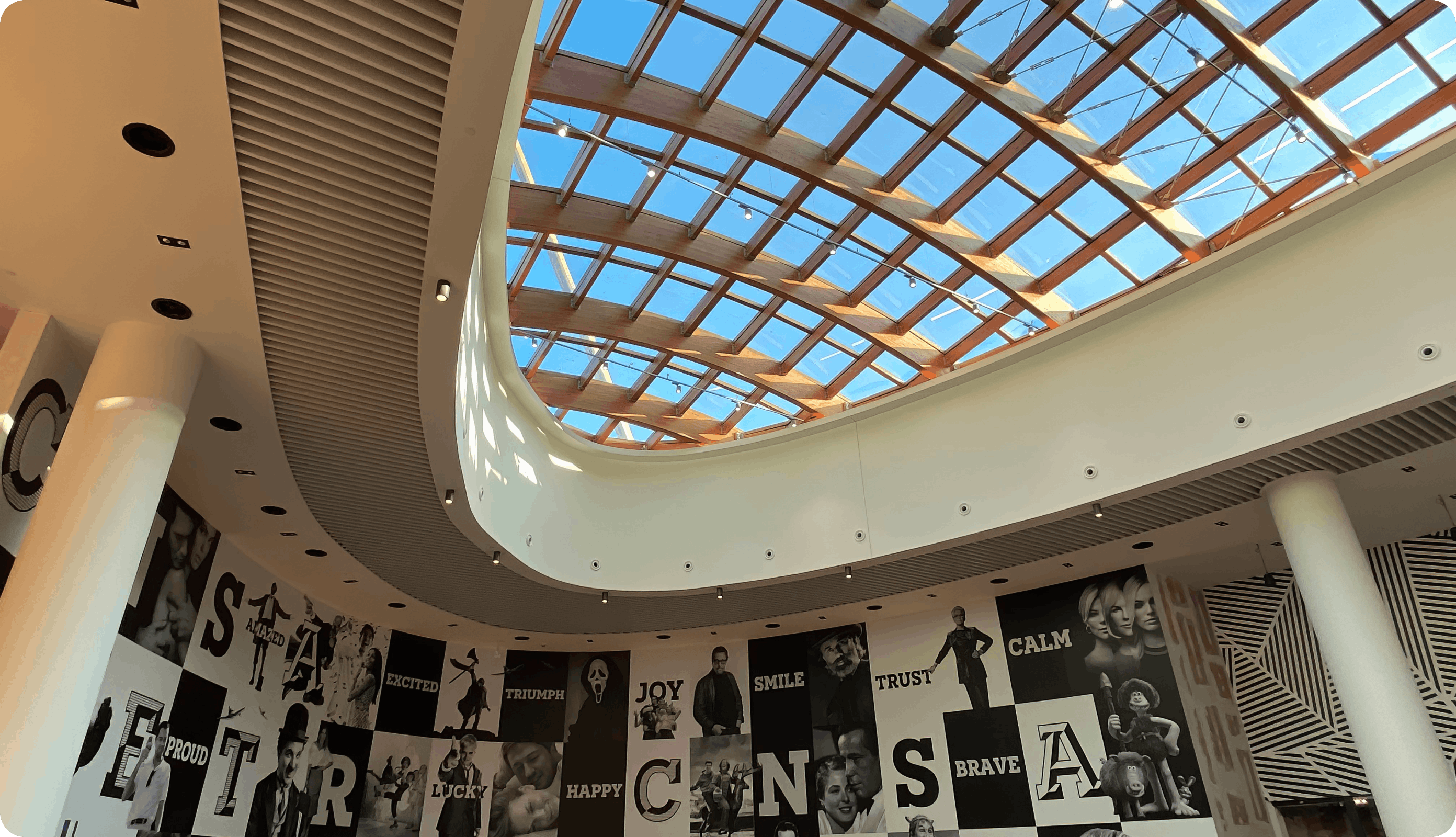

Prishtina Mall, Kosovo

Cathedral of Saint Mother Teresa, Prishtina, Kosovo

UEFA Training Camp, Zenica, Bosnia and Herzegovina

MGallery Tarcin Forest Resort & Spa, Sarajevo, Bosnia and Herzegovina

Matchbox - sport hall Obrenovac, Serbia

Most Duga, Zavidovici, Bosnia and Herzegovina

Elementary Branko Radicevic, Banja Luka, Bosnia and Herzegovina

City Mosque, Zavidovici, Bosnia and Herzegovina

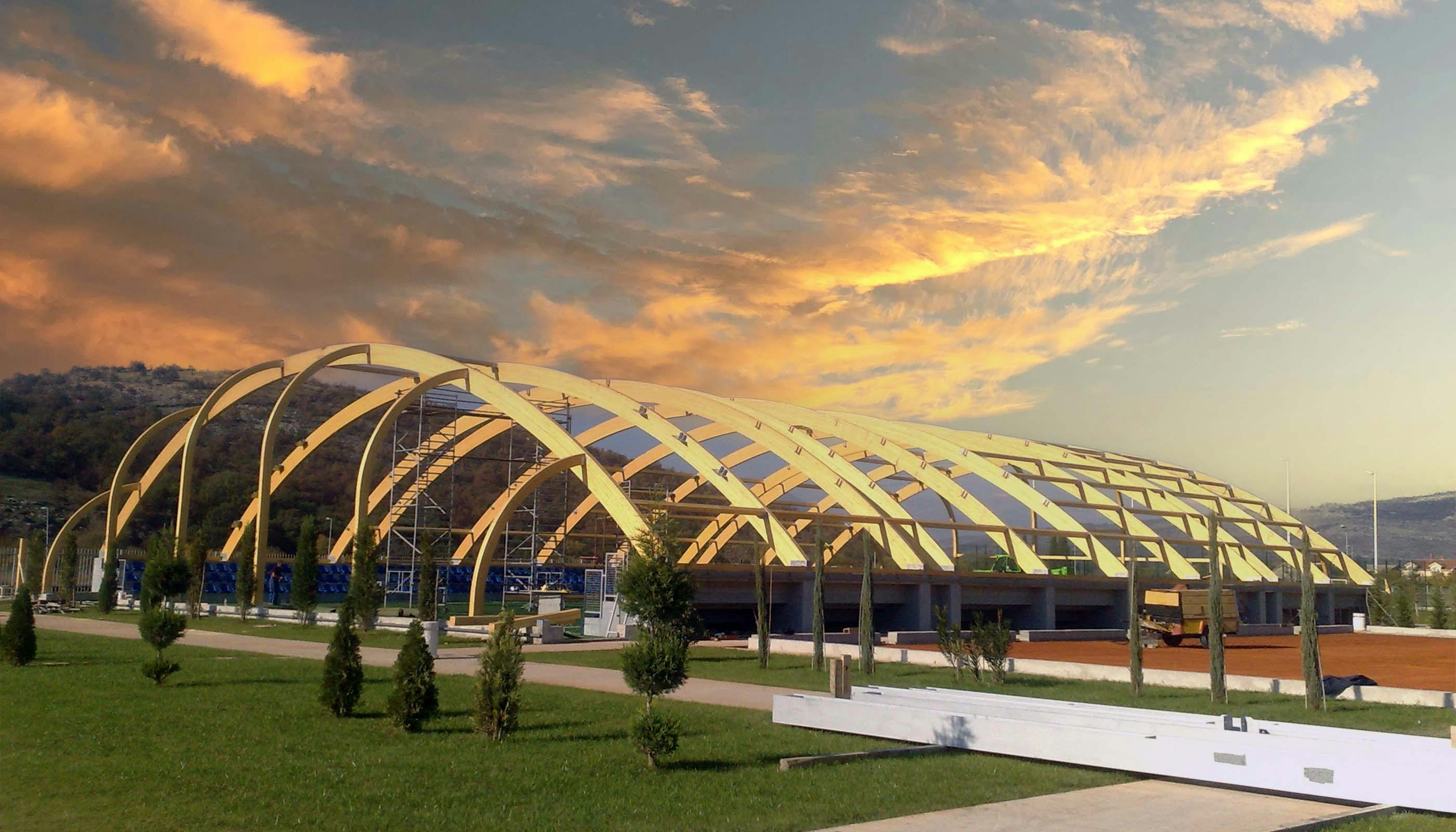

Football Dome, Montenegro

As wood experiences a resurgence in popularity, it is used more and more in both residential and commercial settings. Architects and engineers now embrace wood, particularly glulam, as the eco-friendly building material of choice for "green" construction practices, appreciating its natural beauty and unique attributes.

With a history spanning over 70 years, Krivaja Homes stands as one of the area's oldest and most reliable glulam suppliers. Our extensive experience ensures that you receive unparalleled expertise, encompassing everything from exceptional service and unwavering support to top-notch manufacturing and seamless installation.

Embrace the timeless allure and environmentally conscious qualities of glulam with Krivaja glulam. We combine tradition and innovation to bring your vision to life.

Why glulam?

Unmatched versatility

Glulam offers superior strength, stability, and flexibility with customizable dimensions and shapes for diverse applications.

Lightweight

Glulam beams outperform steel and concrete in strength-to-weight ratio, enabling longer spans with minimal support, resulting in cost-efficient foundations.

Aesthetic appeal

Glulam's natural beauty and warmth enhance architectural designs by allowing exposed structural elements, making it ideal for captivating and architecturally unique structures.

Environment-friendly

Glulam, derived from abundant renewable resources, requires minimal energy for production compared to steel or concrete, contributing positively to carbon storage and environmental impact reduction.

Ease of installation

Familiar timber-handling skills enable straightforward installation, reducing erection times and providing seamless connections for various trades in glulam structures.

Consistent performance

Engineered through glue lamination, Glulam eliminates natural variations, ensuring reliable and predictable performance according to specified criteria.

Fire resistance

Glue laminated timber's controlled burning and char formation allow effective fire design techniques, even with large sections, enabling restoration after fire incidents.

Chemicals resistance

Glulam's resistance to aggressive chemicals makes it suitable for structures storing substances like fertilizers, salt, and acids, making it a preferred choice for environments such as swimming pools and wellness spas.

Unmatched versatility

Glulam offers superior strength, stability, and flexibility with customizable dimensions and shapes for diverse applications.

Aesthetic appeal

Glulam's natural beauty and warmth enhance architectural designs by allowing exposed structural elements, making it ideal for captivating and architecturally unique structures.

Ease of installation

Familiar timber-handling skills enable straightforward installation, reducing erection times and providing seamless connections for various trades in glulam structures.

Fire resistance

Glue laminated timber's controlled burning and char formation allow effective fire design techniques, even with large sections, enabling restoration after fire incidents.

Lightweight

Glulam beams outperform steel and concrete in strength-to-weight ratio, enabling longer spans with minimal support, resulting in cost-efficient foundations.

Environment-friendly

Glulam, derived from abundant renewable resources, requires minimal energy for production compared to steel or concrete, contributing positively to carbon storage and environmental impact reduction.

Consistent performance

Engineered through glue lamination, Glulam eliminates natural variations, ensuring reliable and predictable performance according to specified criteria.

Chemicals resistance

Glulam's resistance to aggressive chemicals makes it suitable for structures storing substances like fertilizers, salt, and acids, making it a preferred choice for environments such as swimming pools and wellness spas.

Technical information

Technical information

TYPE OF WOOD

Spruce / Fir

COLOR OF GLUE LINES

Light coloured glue lines (melamine adhesive)

GRADING

Acc. to EN 14081

DENSITY

Approx. 550 kg / m2

PRODUCT STANDARD

EN 14080 or EN 386

WIDTH

70 - 220

STRENGTH CLASS

GL 24h (EN 14080), BS11 (EN 386)

HEIGHT

80 - 1500

MOISTURE CONTENT

10 to 12 % + / - 2 % on delivery

LENGTH

2 - 55 m (standard size 5 m)

GLUING

Melamine resin-based adhesive

LAMELLA THICKNESS

10/22/32/42 mm

TYPE OF WOOD

Spruce / Fir

GRADING

Acc. to EN 14081

PRODUCT STANDARD

EN 14080 or EN 386

STRENGTH CLASS

GL 24h (EN 14080), BS11 (EN 386)

MOISTURE CONTENT

10 to 12 % + / - 2 % on delivery

GLUING

Melamine resin-based adhesive

COLOR OF GLUE LINES

Light coloured glue lines (melamine adhesive)

DENSITY

Approx. 550 kg / m2

WIDTH

70 - 220

HEIGHT

80 - 1500

LENGTH

2 - 55 m (standard size 5 m)

LAMELLA THICKNESS

10/22/32/42 mm

Quality specifications

Krivaja GLULAM is produced in two different surface qualities:

- Visible Quality - For visible applications (e.g. in residential buildings, schools, sport facilities)

- Industrial Quality - For use in unnoticeable areas (e.g. industrial buildings, agricultural buildings)

CRITERIA

Visible Quality

Industrial Quality

Planned quality:

Roughness not permissible

Roughness permissible

KNOTS:

Firmly intergrown knots permissible

Firmly intergrown knots permissible

KNOT HOLES:

Knot holes up to 10 mm permissible

Knot holes permissible

RESIN POCKETS:

Sizes up to 5x50 mm permissible

Permissible

PITH:

Permissible

Permissible

INSECT INFESTATION:

Not permissible

Permissible

DISCOLOURATIONS:

Blue stain and red steak up to 5% of the visible surface permissible

Permissible

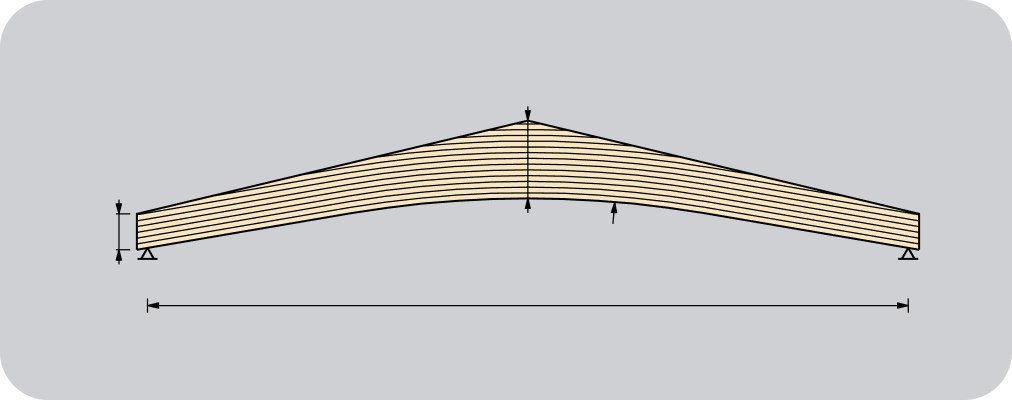

Glulam structural systems

Transport & Delivery

Transport

Components with a maximum length of 13,60 m can be transported in open or closed lorries without any problems. The lorries are loaded in our factories with a side loading fork lift. If unloading by crane is required, this should be agreed in advance with our sales or logistical department. Direct deliveries to a construction site are possible following agreement with our logistics representative.

Our factory in Zavidovici, BiH have a rail connection. Depending on the destination, transport by rail freight may be an economic alternative. Due to glulam's light weight, the transportation costs are much lower than those for steel and concrete.

Due to national and international traffic rules and regulations, components that exceed 13,60 m in length, 2,40 m in width or 2,60 m in height require special transportation that is subject to approval. Our sales and logistics representative are experienced in this sector and always endeavor to find the optimum solution. In order to quote the exact beam dimensions are required. Special transportation must be requested on an individual basis and requires a longer lead- time in the quotation phase than standard transport.

When transported by rail freight the maximum length is up to 48 m, by truck maximum lenght is up to 37 m.

Wrapping

Glulam is normally wrapped in plastic to keep it clean and dry during transport and while it sits on site before erection.

Assembly

Glulam structures can be erected fast and simple, every unit is marked as in project documentation. The parts are assembled by nailing, screwing or bolting, unaffected by the time of year or the weather, and any adjustments can be made with simple hand tools. Glulam elements are connected with steal plates, steal rings and screws for wood. For larger projects assembly is done with the help of crane and scaffold.

A glulam frame can carry its full load immediately after the assembly. It is a well-tested building material which, correctly used, has extremely good durability.

Numerous objects that we have built, over decades, are the best proof of our extraordinary technology and expert work force that can face even the biggest challenges which wood constructions can set before them.

Let’s embark on a journey to create a space that reflects your unique style and needs.